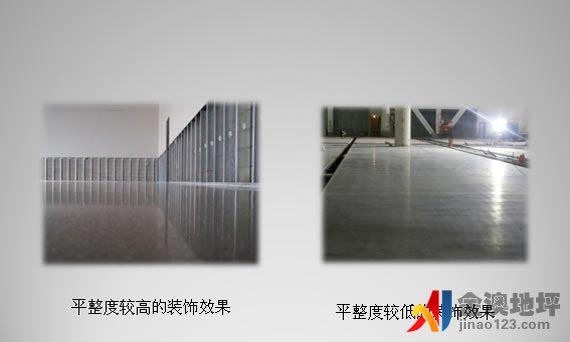

Ukuba ufuna ukwenza umgangatho olungileyo ongagugiyo (okanye umgangatho wokungena osemgangathweni ophezulu), kufuneka ujongane namandla esiseko sekhonkrithi, ingakumbi ukuba sithe tyaba. Umgangatho olungileyo ongagugiyo awunxulunyaniswanga nje kuphela nomgangatho we-aggregate engagugiyo. Kufuneka umhlaba wesiseko ongcono. Eli phepha lijolise ekukunikeni itekhnoloji yokulinganisa i-laser yekhonkrithi ebanzi nepheleleyo kunye nobuchwepheshe bomgangatho ongagugiyo. Oku kulandelayo ziindlela zokwakha ezishwankathelwe yiShanghai Jiezhou Engineering & Mechanism Co., Ltd. ngokweminyaka emininzi yamava kushishino. Njengereferensi yakho.

Inkqubo yokwakha: unyango lwesiseko sendlela → ukuseta ifomwork yokugcina impahla → ukondla ngekhonkrithi → umatshini wokulinganisa i-laser, ukungcangcazela kunye nokuxinana → ukusasaza i-metal aggregate → ukucocwa kwe-calendar kunye ne-slurry → ukupolisha → ukunkcenkceshela kunye nokunyanga → ukusika kunye nokugquma amalungu ngoomatshini.

Umfanekiso wokwakhiwa kwe-laser screed

Unyango olusisiseko

1. Okokuqala, inkunkuma ekwicala elisezantsi mayisuswe kwaye kungabikho ndawo yomileyo phezu komphezulu wecala elisezantsi.

2. Xuba inxalenye ephumayo yomphezulu ukuze umphezulu ulingane. Jonga ukuba indlela esisiseko ihambelana nomgangatho ongaphakathi kwe-± 2cm ukusuka kwindawo ephakanyisiweyo yoyilo ukuqinisekisa ukuba ubukhulu bekhonkrithi bulingana.

Useto lwetemplate

Okokuqala, ngokwendawo yekholamu yentsimbi yesityalo sonke, iimfuno zoyilo, ukulungiswa kwefomwork, indlela yokuhamba kwesithuthi kunye neempawu zokwakha izixhobo zokulenza zibe semgangathweni, kuyayilwa inkqubo yokuthulula yokwakha ethembekileyo. Ifomwork eqinileyo mayifakelwe kwindawo yokwakha. Ifomwork mayibe yifomwork ekhethekileyo eyenziwe ngentsimbi yetshaneli, kwaye ukuvulwa okuphezulu kwefomwork kufuneka kulungiswe ukuze kube tyaba kwaye kuhambelane ngaphakathi nangaphandle.

Seta umaleko otyibilikayo

Emva kokuba ifomwork imisiwe, indawo yokwakha kufuneka igqunywe ngeplastiki ukuze yahlule indlela yesiseko kumphezulu wekhonkrithi ukuze yenze umaleko otyibilikayo.

Ukubopha umnatha wokuqinisa

1. I-reinforcement mesh kufuneka icutshungulwe ngokudityaniswa okuphakathi kunye nokudibeneyo kwindawo leyo, kwaye ithuthwe iye kwindawo ekhethiweyo ukuze ibekwe emva kokubopha. Umphezulu wokuqinisa kufuneka ucoceke, ungabi namdaka, umhlwa, njl. ukuqinisekisa umgangatho wezinto eziluhlaza. I-reinforcement mesh kufuneka ibotshelelwe ngokupheleleyo, kwaye isithuba kunye nobukhulu kufuneka kuhlangatyezwane neemfuno zoyilo kunye neenkcukacha. Emva kokubopha, jonga i-reinforcement mesh ukuze ubone ukuba umaleko okhuselayo wanele na, ukuba i-binding iqinile na kwaye akukho kuthamba.

2. Ngaphambi kokuba kugalelwe ikhonkrithi, kufuneka ifakwe kwindawo emiselweyo ngabasebenzi. Ubungakanani be-reinforcement mesh yi-3M × 3m.

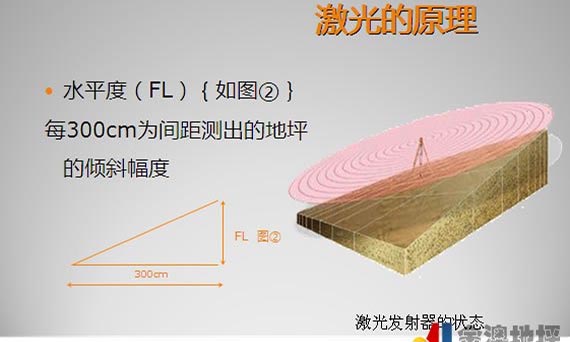

Ukugunyaziswa komatshini wokulinganisa i-laser

Ngaphambi kokugalela ikhonkrithi, umatshini wokulinganisa ilaser kufuneka ulungiswe. Misa kwaye ulinganise i-transmitter yelaser, kwaye ulungise inqanaba kunye nokuphakama kwentloko yokulinganisa yomatshini wokulinganisa ikhonkrithi ngokwesignali edluliselweyo ukuze ihambelane nokuphakama komhlaba wekhonkrithi. Kwangaxeshanye, lungisa umahluko wokuphakama kuzo zombini iziphelo zentloko yokulinganisa ngaphakathi kwe-0.5mm. Ngaphambi kokwakha okukhulu, qala usebenzise izixhobo zokuvavanya imveliso kwaye ujonge ukuqinisekisa ukuba akukho mpazamo.

Ukugalela ikhonkrithi

1. Kuza kusetyenziswa ikhonkrithi yorhwebo. Ukusebenza kwenkonzo yekhonkrithi yorhwebo kuya kuhlangabezana neemfuno zeenkcukacha ezifanelekileyo, kwaye ukudilika kwekhonkrithi kwifomwork kuya kulawulwa kwi-160-180mm.

2. Ikhonkrithi mayigalelwe ukusuka esiphelweni ngendlela ecwangcisiweyo. Xa umxube wekhonkrithi ugalelwa kwifomwork, ukukhutshwa kwempahla kufuneka kuxinaniswe kwaye kucothe, kwaye ubukhulu obubonakalayo bube malunga ne-2cm ngaphezulu kunefomwork. Ukuba kuyimfuneko, izinto kufuneka zincitshiswe okanye zongezwe, kwaye amacandelo athe nkqo nathe tye aya kuhlangabezana neemfuno. Ikhonkrithi mayigalelwe rhoqo ngaphandle kokuphazamiseka.

3. Emva kokuba ikhonkrithi ithululwe, iinqwaba zekhonkrithi mazilinganiswe ngesandla ngaphakathi koluhlu olusebenzayo lwengalo yeteleskopu yomatshini wokulinganisa, kwaye emva koko ukungcangcazela, ukuxinana kunye nokulinganisa kufuneka kugqitywe ngaxeshanye ngomatshini wokulinganisa welaser. Kwinkqubo yokulinganisa, thatha icala elinye njengomgaqo, uze ulale ngasemva ukusuka ngaphakathi ukuya ngaphandle inyathelo ngenyathelo.

4. Iindawo apho ulwakhiwo loomatshini lungenakwenziwa khona, njengeekona kunye neekholamu zentsimbi, kufuneka ziqiniswe kwaye zilinganiswe ngesandla.

Ulwakhiwo lomgangatho olumelana nokunxitywa

Ngaphambi kokuseta okokuqala ikhonkrithi, i-disc trowel mayisetyenziswe ukuplasta ide ikhuphe i-slurry, kwaye i-hardener mayisasazwe ngokulinganayo kumphezulu wekhonkrithi. Emva kokuba i-hardener ifunxe amanzi athile, qala ukugaya; Emva kokugaya okurhabaxa, umaleko wesibini we-hardener kufuneka usasazwe, kwaye ubungakanani bezinto kufuneka bube yi-1/3 yenkqubo yangaphambili. Ukugaya okunqamlezileyo kufuneka kwenziwe ngexesha lokugaya, kwaye akukho kugaywa okulahlekileyo okuvunyelweyo.

Ukuxinana kunye nokupolisha ngetrowel

1. Emva kokulinganisa nge-laser, ikhonkrithi kufuneka iphakanyiswe ize igqitywe nge-trowel ngaphambi nasemva kokuseta kokuqala. Ukusebenza kwe-trowel ye-disc grinder kufuneka kwenziwe amaxesha amaninzi ngokwendlela yokuqina komphezulu womphezulu. Isantya sokusebenza kwe-trowel yoomatshini kufuneka silungiswe ngokufanelekileyo ngokwendlela yokuqina komhlaba wekhonkrithi, kwaye umsebenzi we-trowel yoomatshini kufuneka wenziwe ngokuthe nkqo nangokuthe tye.

2. Ngaphambi kokuseta kokugqibela, tshintsha idiski yegrinder njengeblade, kwaye ulungise i-engile yokusila nokupolisha. Ngokubanzi, umsebenzi wokupolisha uphindaphinda ngaphezu kwezihlandlo ezi-2 ukuze wenze i-floor gloss ifane.

Umngxuma:Izihlanganisi mazisikwe ngexesha le-2-3D emva kokwakhiwa kwendlela yomphezulu engagugiyo. Ukusika okumanzi kufuneka kusetyenziswe kwizihlanganisi zokusika, ezinobukhulu obuyi-5cm kunye nobunzulu obungaphantsi kwe-1/3 yobukhulu bekhonkrithi. Umthungo wokusika kufuneka uthe tye kwaye ube mhle.

Unyango: Emva kokuba ikhonkrithi ipolishiwe, kufuneka igqunywe ngefilimu ize iniselwe ukuze inyibilike. Ngexesha lokunyibilika, xa amandla ekhonkrithi omphezulu engafikeleli kwi-1.2MPa, akukho mntu uya kuhamba kuyo.

Ukugquma nge-caulking

1. Emva kokuba umgangatho ulungisiwe kangangeeveki ezimbini, hlamba kakuhle indawo yokusikela uze ususe zonke iinxalenye ezikhululekileyo kunye nothuli kwindawo yokusikela.

2. I-polyurethane sealant enokuqina okuhlala ixesha elide kunye nokuqina okukhawulezayo kufuneka isetyenziselwe ukuzalisa i-shrinkage joint.

Amanyathelo okulawula

1. Izinto ezisetyenziswa kwindawo kufuneka zamkelwe kwindawo, kwaye mazibekwe kwindawo emiselweyo emva kokudlula ukwamkelwa. Qaphela ukuba izinto ezifunekayo ukuze zingangeni manzi kufuneka zithathe amanyathelo afanelekileyo ngokuchasene nokufuma kunye nemvula.

2. Ukubonelela ngabasebenzi abanamava kulawulo lokwakha kunye nabasebenzi abanobuchule bokwakha. Ngaphambi kokwakha, abasebenzi abafanelekileyo baya kucwangciswa ukuba benze utyhilelo lobuchwephesha malunga nokusetyenziswa ngokuchanekileyo koomatshini bokwakha kunye nezixhobo kunye nolawulo lweenkqubo eziphambili, ukuqinisekisa ukuba abasebenzi bokwakha banobuchule ekusebenzeni kwenkqubo nganye.

3. Oomatshini bokwakha nezixhobo kufuneka bahlangabezane neemfuno, babe kwimeko entle, kwaye balungiselele ezinye izixhobo ezibalulekileyo.

4. Indawo yokwakha indawo mayigcinwe icocekile kwaye icocekile ukuthintela uthuli nezinye izinto ezomileyo ukuba zingangcolisi umhlaba.

5. Iipokotho, inkunkuma kunye nezinye izinto ezilahliweyo ezishiywe kwindawo kufuneka zisuswe yonke imihla ukuqinisekisa ukuba indawo icocekile emva komsebenzi. Kwimeko yezinto ezikhethekileyo zenkunkuma, indlela yokucoca kufuneka ihambelane neemfuno zokucoca izinto ezikhethekileyo.

Okokugqibela, ukongeza ekulandeleni ngokungqongqo ezi nkqubo zingasentla, umgangatho olungileyo omelana nokuguguleka ufuna ulungelelwaniso kunye nentsebenziswano phakathi kwekhonkrithi kunye nomgangatho omelana nokuguguleka.

Yasekwa ngo-1983, iShanghai Jiezhou Engineering & Mechanism Co., Ltd. igxile kwi-R & D, imveliso kunye nokuthengiswa koomatshini kwicandelo lomgangatho wekhonkrithi. Umatshini we-laser screed, i-power trowel, umatshini wokusika, i-plate compactor, i-tamping rammer kunye neminye imishini isebenzisa ubuchwepheshe bamva nje kwaye inconywa kakhulu ngabathengi.

Inabathengi kumazwe angaphezu kwe-100 kwihlabathi liphela kwaye ikhokela kushishino. Ukuba unemibuzo, ungatsalela umnxeba i-DYNAMIC, kwaye siya kukukhonza ngentliziyo yonke!

Ixesha lokuthumela: Agasti-24-2022